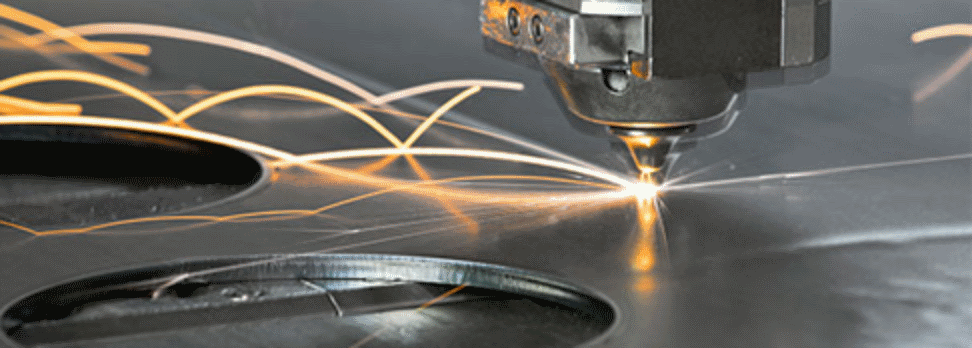

Brunner Industries utilizes Mitsubishi Lasers in both our industrial fabrication and our semi-truck accessory production. Laser cutting is among the most advanced piercing and cutting technology, and guarantees the highest level of accuracy when wet-cutting metal. Other benefits of the Mitsubishi Laser include:

High Cutting Speed

Time is an essential limiting factor in any manufacturing process. Our Mitsubishi Laser cutting machine utilizes fiber technology, providing a more efficient beam and a higher metal-cutting speed.

Fine Profile Detail

When it comes to fabrication, the devil is in the details. Laser cutting gives us the precision we need, whether we’re cutting sheet metal or a one-inch plate. Laser technology ensures superior accuracy, even when cutting highly complex holes and shapes.

Exceptional Edge Quality

The quality of a cut is determined by the edge it leaves on the metal. Improper cuts can create risks for those working the cut metal, slowing production and possibly causing injury. Brunner laser cutting ensures safe, smooth edges—exceptional quality with no further refining needed.

Versatility

We have the capability to meet your unique needs, from different metal types to specific sizing. Our Mitsubishi Laser can cut stainless steel, mild steel, aluminum, and even titanium. Thickness is no issue; we can accommodate any metal sheet between 0.2 millimeters and 25 millimeters thick.